Modcon Systems Recognized with Best Industrial Sensing Technology Award for Oxygen Monitoring

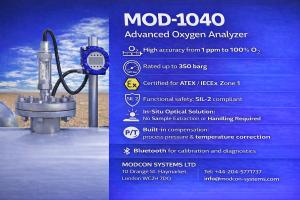

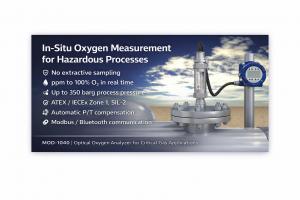

MOD-1040 Process Oxygen Analyzer designed for real-time, in-situ oxygen monitoring in safety-critical industrial environments.

Modcon Systems earns recognition for advanced oxygen monitoring technology supporting safety, efficiency, and AI-enabled process control.

The award recognizes Modcon’s continued innovation in industrial measurement, particularly its real-time oxygen analyzer technologies that provide continuous, in-situ data from demanding process environments. As industrial systems become more automated and digitally optimized, accurate physical measurement remains essential to ensuring that control strategies, digital twins, and artificial intelligence models remain aligned with real operating conditions.

Oxygen monitoring plays a critical role in many industrial processes. Even trace levels of oxygen can significantly affect process safety, product quality, equipment integrity, and environmental performance. In hydrogen production systems, uncontrolled oxygen ingress can lead to hazardous mixtures. In refineries, petrochemical plants, and natural gas operations, oxygen exposure accelerates corrosion, degrades catalysts, disrupts combustion stability, and increases the risk of unplanned shutdowns.

As a result, reliable oxygen monitoring has become a foundational requirement for modern process control architectures. High-performance oxygen sensor and O2 sensor technologies provide operators with the real-time insight needed to detect deviations early and take corrective action before risks escalate.

The Best Industrial Sensing Technology Award acknowledges Modcon Systems’ ability to deliver this level of precision and reliability in environments where conventional measurement approaches often fall short.

At the core of Modcon’s recognition is its advanced process oxygen analyzer platform, which utilizes optical sensing technology based on quenched fluorescence. Unlike traditional electrochemical or paramagnetic methods, this optical approach enables fast response times, high sensitivity, and long-term measurement stability, even in harsh industrial conditions.

Key features of the award-winning technology include:

* Continuous in-situ oxygen measurement without reliance on extractive sampling

* High sensitivity for early detection of oxygen ingress at low concentration levels

* Stable performance in high-pressure, high-temperature, and corrosive process streams

* Reduced maintenance requirements compared with conventional O2 sensor designs

These characteristics make the analyzer suitable for safety-critical applications in hydrogen production units, natural gas processing facilities, refinery process units, flare systems and petrochemical plants.

Industrial oxygen measurement frequently takes place in classified and hazardous zones. Modcon’s analyzer probes are designed with safety as a primary consideration, containing no electrical components or moving parts at the measurement point. This design minimizes ignition risks commonly associated with traditional oxygen sensor installations in explosive atmospheres.

Each analyzer system is supported by a dedicated sample conditioning and protection concept that ensures the measured sample is clean, stable, and representative of the process. This approach supports both measurement accuracy and regulatory compliance, while maintaining safe operation in demanding environments.

Real-time oxygen monitoring delivers value across multiple dimensions of industrial performance:

* Process safety: Early identification of oxygen ingress reduces the risk of combustion, explosion, and equipment damage.

* Operational efficiency: Continuous feedback allows tighter process control, minimizing waste, process drift, and unplanned downtime.

* Environmental performance: Stable combustion and optimized process conditions help reduce emissions and energy consumption.

By providing accurate, real-time oxygen data, Modcon’s analyzer systems enable operators to move from reactive troubleshooting toward proactive, data-driven process management.

To ensure measurement accuracy under real operating conditions, Modcon’s oxygen analyzer incorporates automatic pressure and temperature (P/T) compensation, correcting oxygen readings for process fluctuations in pressure and thermal conditions. This capability is critical in hydrogen, refining, and gas-processing applications where operating conditions vary dynamically and uncompensated measurements can lead to control errors. In parallel, the analyzer supports modern industrial communication protocols, including Modbus for seamless integration with DCS, PLC, and SCADA systems, as well as Bluetooth communication for local diagnostics, commissioning, and maintenance. This combination enables both robust plant-wide data integration and secure, efficient field-level access for operators and service personnel.

Beyond measurement alone, Modcon Systems integrates analyzer data into Modcon.AI, its AI-driven optimization platform. Modcon.AI connects live sensor data with machine learning models and digital twins to support predictive analytics, adaptive control strategies, and continuous optimization.

Using real-time input from sensor O2 measurements, the platform evaluates process behavior, predicts potential deviations, and refines control setpoints. This closed-loop architecture ensures that artificial intelligence remains continuously calibrated against verified physical data, improving reliability and long-term operational performance.

Modcon Systems Ltd. is a London-based provider of industrial process analyzers and advanced optimization technologies. With decades of experience serving refining, petrochemical, and energy markets, the company delivers integrated solutions covering oxygen monitoring, gas and liquid analysis, analyzer shelters, and AI-driven process optimization. Modcon’s technologies are deployed worldwide to improve safety, efficiency, and sustainability in industrial operations.

Anya Alter

Modcon Systems Ltd.

+44 204-5771737

email us here

Visit us on social media:

LinkedIn

YouTube

Award-winning oxygen monitoring connects AI to real-world measurement

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.